Liquefied gas tank level measurement

Liquefied gas tank level measurement

Media

Manufacturers

Technical Specifications

Equipment and devices: meter transmitters, meter receivers, remote monitoring systems, level control devices, level measurement devices

Other designations: LPG tank level measurement, liquid gas tank level measurement

What is liquefied gas tank level measurement?

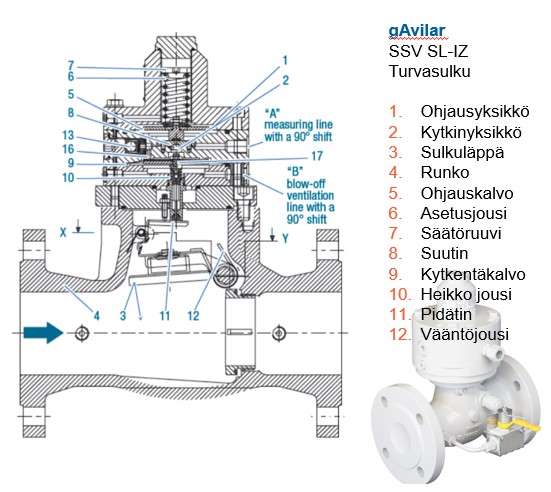

Liquefied gas tank level measurement monitors the tank’s surface level and the quantity of gas. The measuring equipment includes meter transmitters, meter receivers, remote monitoring systems, level control devices, and level measurement devices.

Selection of liquefied gas tank level measurement devices

We always assist in selecting level measurement devices that meet the requirements of the application.

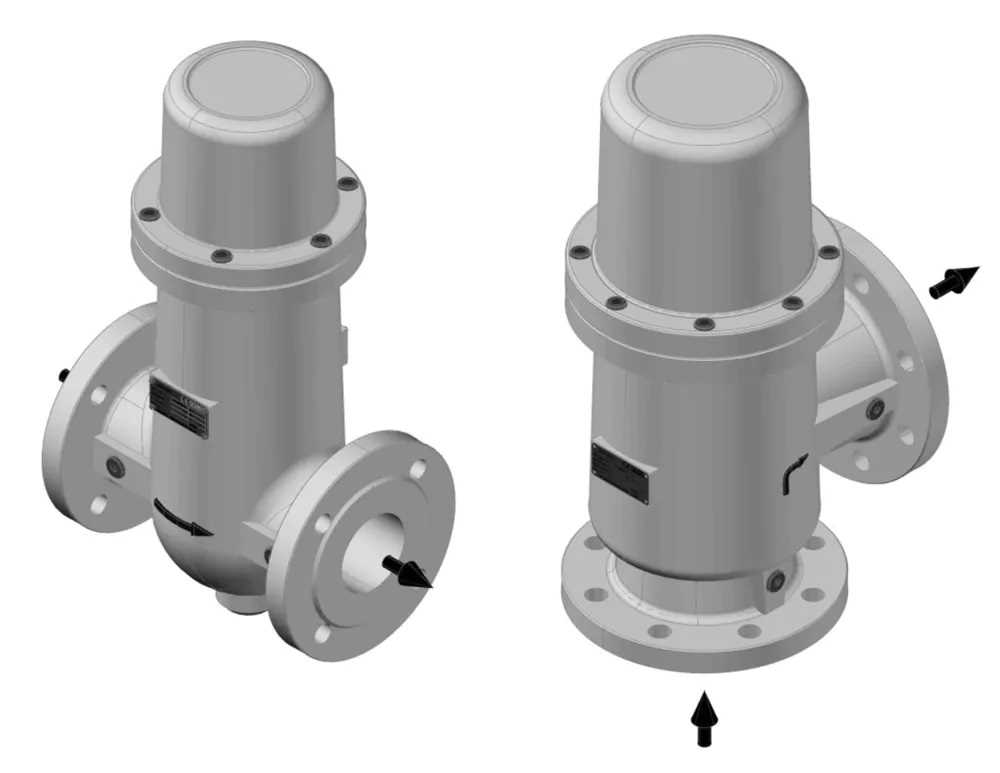

Monitoring the surface level of tanks is one of the most important measurement applications in the process industry. Both continuous level measurement and level switches are used when measuring the surface.

Rochester gauges – float level indicators transmit information about the storage tanks’ surface level to a mechanical pointer display. A transmitter can be integrated into the display, which sends the information to the control room or level monitoring system.

Factors influencing the selection of a float level transmitter include the medium, temperature, tank size, and installation method. In addition to mechanical float level transmitters, the range includes various devices for processing level data, such as current and voltage transmitters and converters. Float level transmitters are suitable for monitoring the surface levels of various liquids, such as chemicals and petrochemical products, propane, butane, ammonia, and refrigerants.

Level switches transmit the information that the surface has reached a predetermined height. The system controls the process based on this data.

A level indicator allows you to see locally at what height the surface is in the tank.

Meter Receivers for Liquid Gas

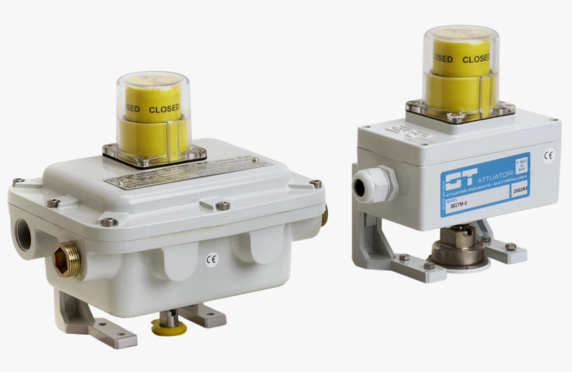

The message from the float level transmitter can be received, for example, by an analog volume indicator or by a low/high limit alarm installed in the control room.

Remote Monitoring Systems for Liquid Gas

With Rochester’s wired CSU-3 digital receiver, limit alarms can be transmitted directly to a PC. The device features adjustable fill limit alarms, a 4-20 mA output, and relay outputs.

Contact our representatives for more details.