Conductivity measurement

Conductivity measurement

Media

Manufacturers

Technical specifications

Other designations: conductivity measurement

What is steam boiler conductivity measurement?

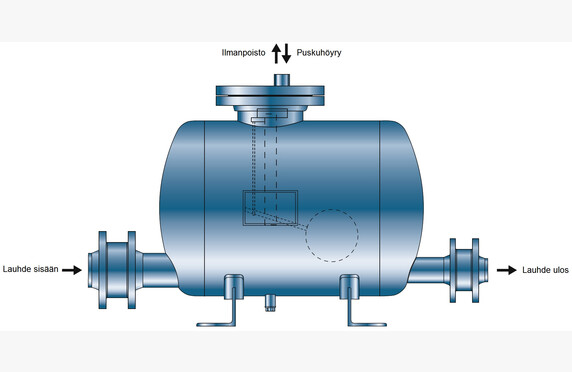

Conductivity measurement is used primarily in steam boilers to monitor boiler water and condensate. Limit values are set for the quality of the boiler water, which the conductivity measurement monitors. If the water quality deviates from the limit value, the sensor indicates the change to the system, based on which the surface blowdown / boiler conductivity is adjusted.

Proper boiler water conductivity is important not only for the internal condition of the boiler and minimized maintenance, but also because an effective conductivity measurement achieves an optimized water blowdown rate. In this case, as little make-up water as possible is required.

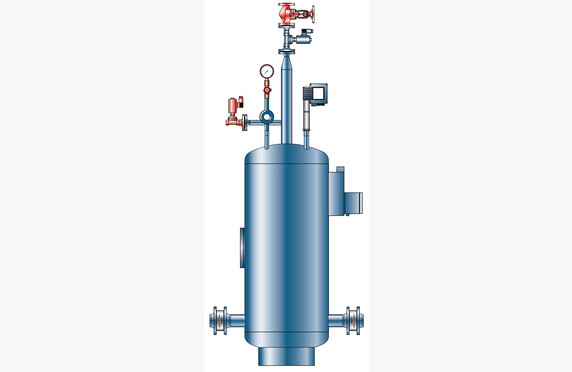

Conductivity measurement can also be used as a leak detector, for example in heat exchangers where two intermediary fluids with different electrical conductivities are used. If a leak occurs in the heat exchanger and the fluids mix, the conductivity sensor immediately triggers an alarm in the system.

Selection of Conductivity Measurement Devices

We assist in selecting measurement devices that meet the application’s requirements.

GESTRA LRG and LRGT conductivity sensors are available with either manual or automatic temperature compensation. The conductivity signal is forwarded via an active transmitter integrated into the sensor (output signal 4-20 mA) or by using a separate amplifier, which allows digital communication between the sensor and the amplifier. The conductivity of the medium to be measured must be at least 0.5 µS/cm.

GESTRA also offers the LRS 1-7a controller for conductivity sensors, which can, among other things, control a three-way valve to reject dirty condensate.

Contact our representatives for more information.

Download Brochures

GESTRA LRR1-50, LRR1-51 Conductivity Controllers

Lataa PDF

GESTRA LRR1-52, LRR1-53, URB50 Conductivity Controllers

Lataa PDF

GESTRA LRR1-60 Conductivity Controller

Lataa PDF

GESTRA LRG16-4 Conductivity Electrodes

Lataa PDF

GESTRA LRG16-9 Conductivity Electrode

Lataa PDF

GESTRA LRG16-60, LRG16-61, LRG17-60 Conductivity Electrodes

Lataa PDF

GESTRA LRGS15-1 Conductivity Switch

Lataa PDF

GESTRA LRGT16-3, LGRT16-4, LRGT17-3 Conductivity Transmitter

Lataa PDF

GESTRA LRS1-7 Conductivity Switch

Lataa PDF

GESTRA LRS1-50 Conductivity Switch

Lataa PDF