Thermostatic steam traps

Thermostatic steam traps

Media

Manufacturers

Technical specifications

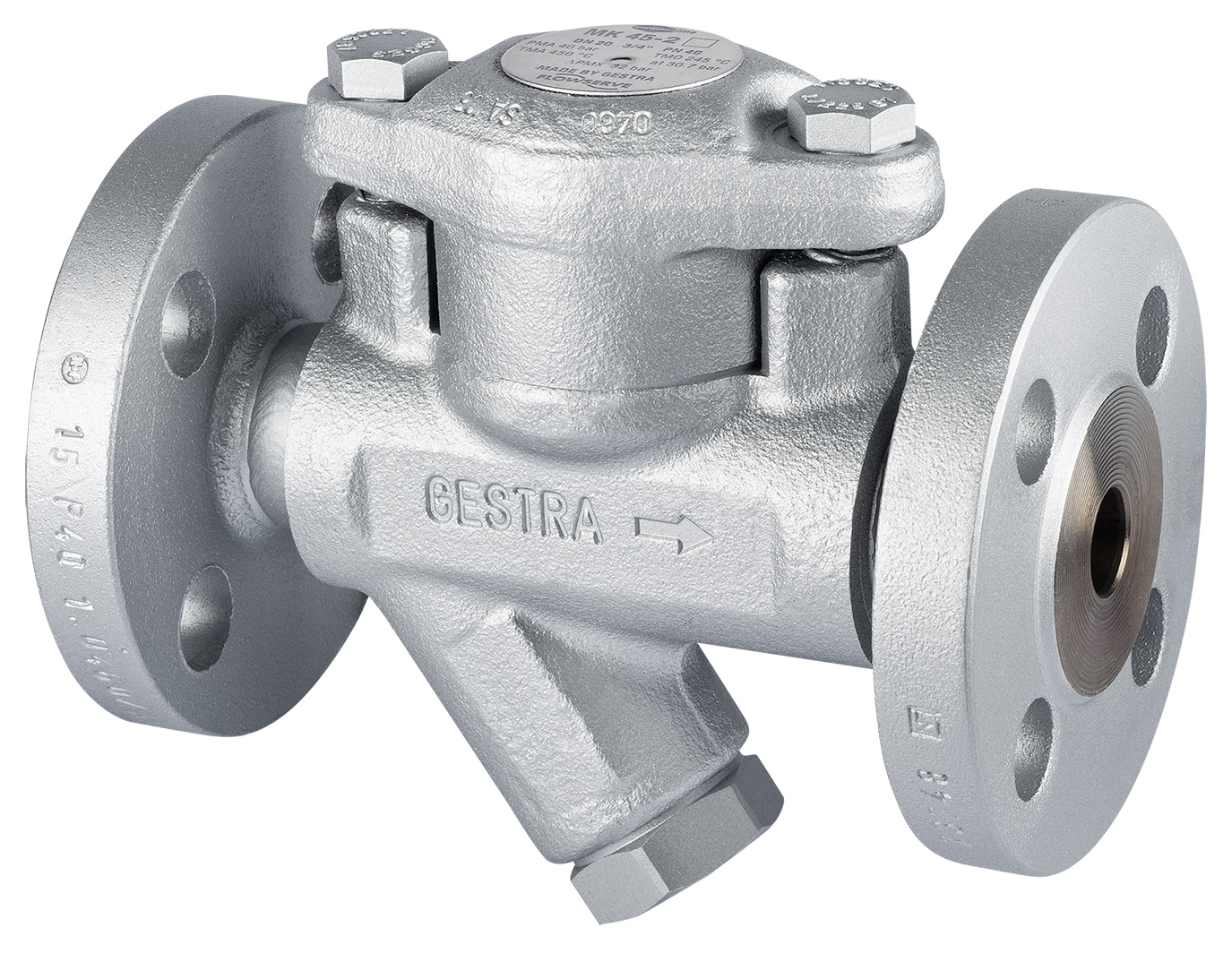

Sizes: DN 15-50

Pressure rating: PN 40

Materials: C22.8, AISI 316L

Connection method: Flanged, threaded, welded socket, welded neck

Other names: thermal condensate drain

What is a thermostatic steam trap?

The operating principle of thermostatic steam traps is in a pressure/temperature-controlled mono-membrane regulator. The regulator’s control medium is an alcohol-water mixture. By adding alcohol to the water, its boiling point is lowered compared to that of pure water.

This technique results in a rapidly operating steam trap that closes itself just before live steam flows through it. In this way, the live steam losses of the trap are 0 kg/h.

Selection of a thermostatic steam trap

The GESTRA MK model is ideally suited for applications where pressures and steam quantities are relatively low. Thanks to its rapid response, it operates in systems where loads vary quickly or the system needs to be frequently opened or closed.

Due to the excellent air removal capabilities of thermostatic traps, they are also suitable for air and gas removal in steam systems. The MK series traps are suitable for both indoor and outdoor use.

The model includes an integrated check. However, it should be noted that the check design is not spring-loaded. The force of “pressureless” backflows is not sufficient by itself to close the trap. In such cases, an additional check valve is recommended.