Changeover valves

Changeover valves

Media

Manufacturers

Technical specifications

Size ranges: DN 15 – 600, ASME: NPS ½“ – 24“

Pressure classes: PN 10 – 400/ Class 150 – 2500

Other: plug or poppet type

Other designations: change over valves

What is a changeover valve?

A changeover valve is a device used to divert flow from one pipe to another. The most typical changeover valve application is in connection with two safety valves, where paired safety valves are connected to the inlet and outlet pipe by changeover valves that are interconnected. In this case, one safety valve can remain in operation while the other is taken out of service by turning a hand wheel.

Selection of changeover valve

We assist in the selection and sizing of a changeover valve according to the application requirements.

For process media

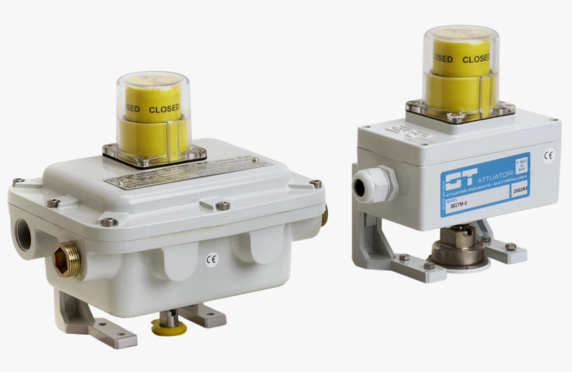

A changeover valve can be implemented in several ways. A plug-type changeover valve can be used, in which a shut-off element is located in the center of a Y-shaped body. It has seals on both sides. The valve seals one seal against the other when the other is fully open. Examples include changeover valves manufactured by ARIN, FEMAN and Descote. A flanged version of the Descote changeover valve is also available.

Another way to implement a changeover valve is to use a three-way plug valve. This way, the advantages of a plug valve can be utilized. For example, when dealing with challenging chemicals, one option is to use a lined three-way plug valve. In AZ’s range there is a changeover valve system that features two three-way plug valves connected to the same actuator.

For cryogenic media

Unlike a standard ball valve, a changeover valve has at least two safety valves. Their purpose is to protect the system (e.g. a liquefied gas tank) from overpressure. Thus, the changeover valve connects two safety valves to the pressure device. In a changeover valve, there are usually two outlets but only one inlet. Changeover valves are used when the medium is a cryogenic liquefied gas, such as nitrogen.

Changeover valves are available in sizes DN 15-50. They withstand pressures up to 250 bar at temperatures from -270 °C to +400 °C. Changeover valves are mainly manufactured in stainless steel, but also in bronze and brass.