Energy calculation and compensation units

Energy calculation and compensation units

Media

Manufacturers

Technical Specifications

Supply voltage: 24 V DC or 230 V AC

Analog inputs: 2-4 pcs

PT inputs: 2 pcs

Digital inputs: 2-6 pcs

Analog outputs: 2-6 pcs

Digital outputs: 3-7 pcs

Interfaces: M-Bus, RS232, RS485, Ethernet, Profibus DP

Protocols: M-Bus, Profibus DP, Modbus (ASCII, RTU, TCP/IP)

Other designations: calculation and compensation units

What are Energy Meters and Compensation Units?

Flow meters provide their measurement results based on the pressure and temperature values set on them. In reality, however, the process values can fluctuate on both sides of the set values, and the role of the compensation units is to perform this correction. Especially in billing applications, it is important to know the flow rate very accurately.

The calculation unit determines the values for volumetric and mass flow as well as energy. To achieve high precision, pressure- and temperature-dependent variables are continuously corrected.

Selection of Energy Meters and Compensation Units

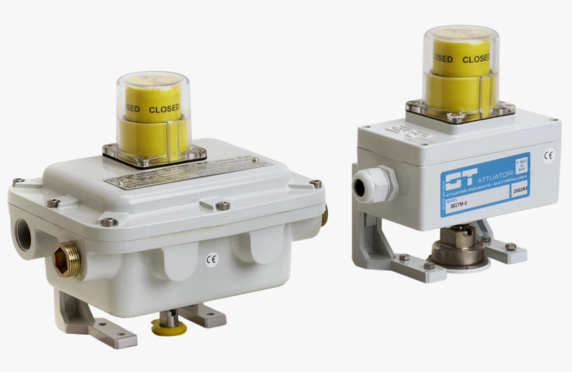

The meters are delivered either as panel-mounted units or as ready-to-install wall-mounting enclosures. We assist with the selection of equipment according to the requirements of the application. Ask our contacts for more information.

For Steam and Condensate

METRA ERW 700 meets the calculation requirements for steam billing measurements in accordance with SFS-EN ISO 5167.

The meter comes pre-programmed with a flow calculation equation, discharge coefficients for pressure difference devices for different opening ratios and measurement methods, as well as expansion coefficients for various media.

The IAP WS IF 97 steam tables are used in the calculation.

Metal expands when heated. In billing measurements, temperature changes are taken into account by adjusting the size of the flow opening of the pressure difference device based on the temperature measurement and the pre-programmed thermal expansion coefficient.

In energy calculations, the energy of the returning condensate can also be taken into account and deducted from the total energy consumed.

For Process Fluids

METRA ERW 700 is a MID-approved unit for calculating flow and energy of district heating.

The calculation unit receives the flow rate and temperature(s). Based on the data, the consumed energy is calculated.

The specific heat capacity of a water/glycol mixture is different from that of water.

In heating/cooling systems that use a water/glycol mixture, the specific heat capacity of the medium can be programmed. The specific heat capacity of a water/glycol mixture depends on the temperature and deviates significantly from that of water.

The specific heat capacity of the medium can be programmed into the ERW 700 energy meter, ensuring the accuracy of the energy calculation.

For Gases and Liquid Fuels

The volumetric flow of liquid fuels can be converted to mass flow by taking temperature into account and calculating the density at the measured temperature.

Measurement of natural gas quantity is based on the measurement of volumetric flow. Due to compressibility, in addition to the measured volumetric flow, the prevailing pressure and temperature conditions during measurement must be considered. The measured volumetric flow of natural gas is converted to normal conditions (0 ºC and 1.01325 bar). In precise measurements, a compressibility factor is also taken into account, because natural gas behaves somewhat differently from an ideal gas, especially at higher pressures.

The calculation methods used for gaseous media are:

- ideal gas law

- Redlich-Kwong

- GERG 88

- flow correction taking temperature, pressure, and compressibility into account

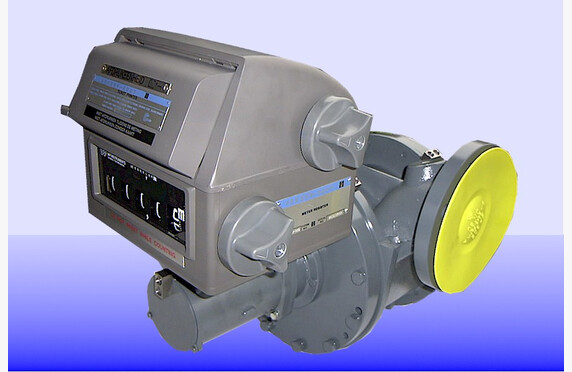

The METRA ERW 700 calculation unit determines the values for volumetric and mass flow as well as energy. To achieve high precision, pressure- and temperature-dependent variables are continuously corrected.

Download Brochures

METRA ERW 700 Electronic Flow Computer

Lataa PDF