CO2 vaporizers

CO2 vaporizers

Media

Manufacturers

Technical specifications

Other names: CO2 vaporizer, CO2 vaporizer, carbon dioxide vaporizer

What is a Carbon Dioxide Vaporizer?

The function of the vaporizer is to convert carbon dioxide in a controlled manner from liquid phase to gas phase, allowing it to be used as a process gas. The carbon dioxide vaporizer – i.e. CO2 vaporizer – is based on an LPG vaporizer, but some components have been replaced so that the device is better suited for CO2 use.

Choosing a Carbon Dioxide Vaporizer

We assist in selecting a carbon dioxide vaporizer that meets the requirements of the application.

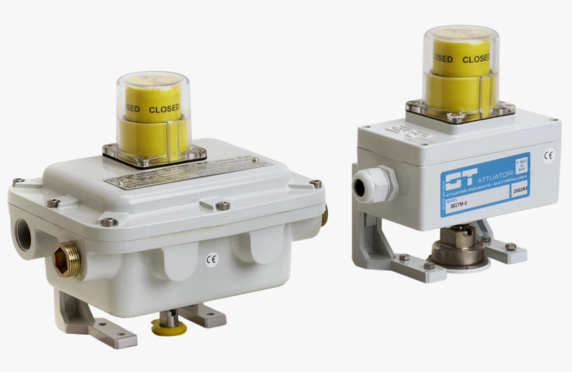

T.A.G. also supplies vaporizers for carbon dioxide. These vaporizers can be equipped with various safety devices and, for example, with a small cabinet if the installation takes place outdoors.

Contact our representatives for more information.