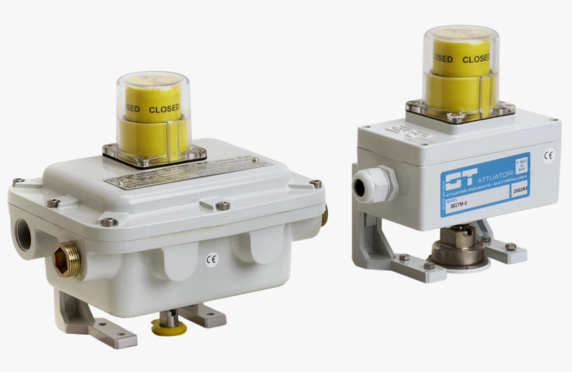

Limit switches

Limit switches

Media

Manufacturers

Technical specifications

Other names: valve limit switch, valve position indicator, signal box

What is a valve limit switch?

Using limit switches, the system can easily and reliably obtain, for example, valve open/close status data, which can be further transmitted electronically to the control system.

In mechanical models, a switch is installed on the valve yoke that opens or closes with the movement of the valve. In this way, information on whether the valve is open or closed is obtained.

The inductive switch sends a trigger signal when metal or another electrically conductive material approaches the sensing surface.

The operation of the magnetic switch is based on changes in the magnetic field when the valve yoke rises or falls.

Limit Switch Selection

Our program includes mechanical, inductive, and magnetic limit switches. We assist in selecting the limit switch that meets the application’s requirements, including for ATEX zones.

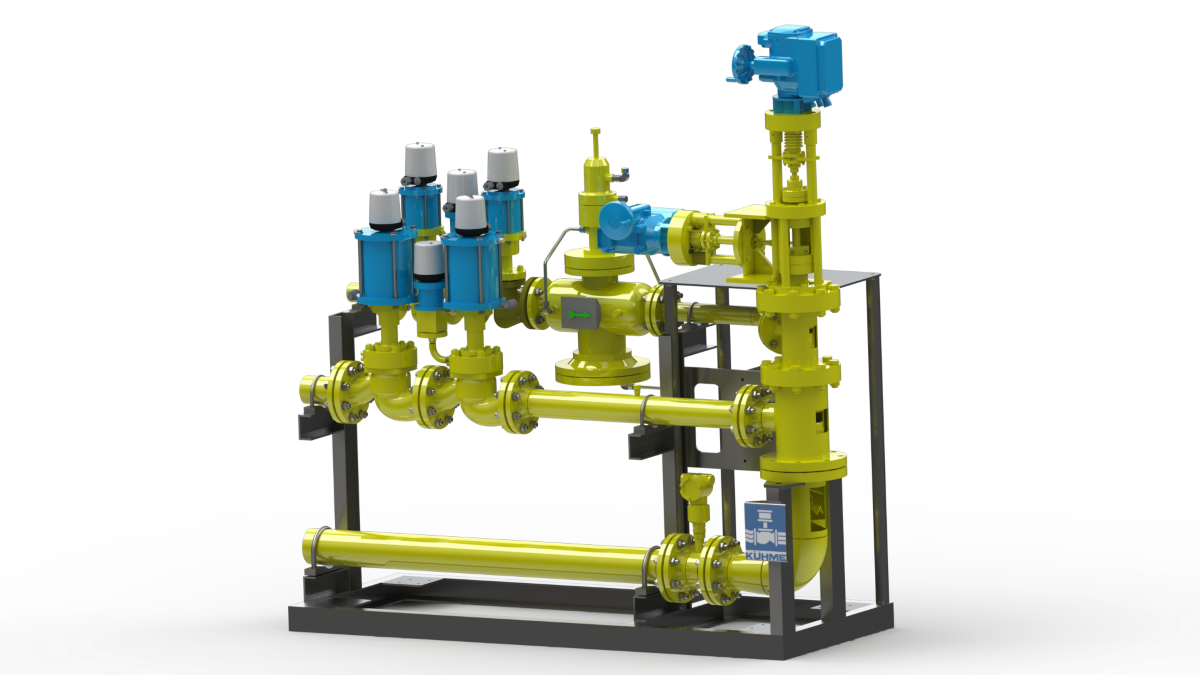

Netherlocks, part of the Sofis group, manufactures compact VPI open/closed limit packages, which can be installed on virtually any existing valve. Both on rotary-operating valves and on manually operated screw valves. Our installation service measures the necessary dimensions from the existing valve for the intermediary parts. After delivery, we proceed to install and set up the limit package.

Contact our representatives for more information.