Teflon lined butterfly valves

Teflon lined butterfly valves

Media

Manufacturers

Technical specifications

Sizes: DN 50–600, ASME

Pressure Classes: PN 10–16, ANSI 150#

Operating Temperatures: -40 °C…+200 °C (UHMWPE lining 85 °C)

Operating Pressures: 1 mbar–16 bar

Flanged Connections: installed between flanges, lug type end flange

Other: FDA approval (white PTFE and antistatic lining), TA-Luft highest class DIN15848, A – 35 kV spark test, MTBF classification EN 61508 SIL2, non-slam baffle according to standard EN 731-3, PED 2014/68/EU, ATEX

Other Names: teflon lined butterfly valve

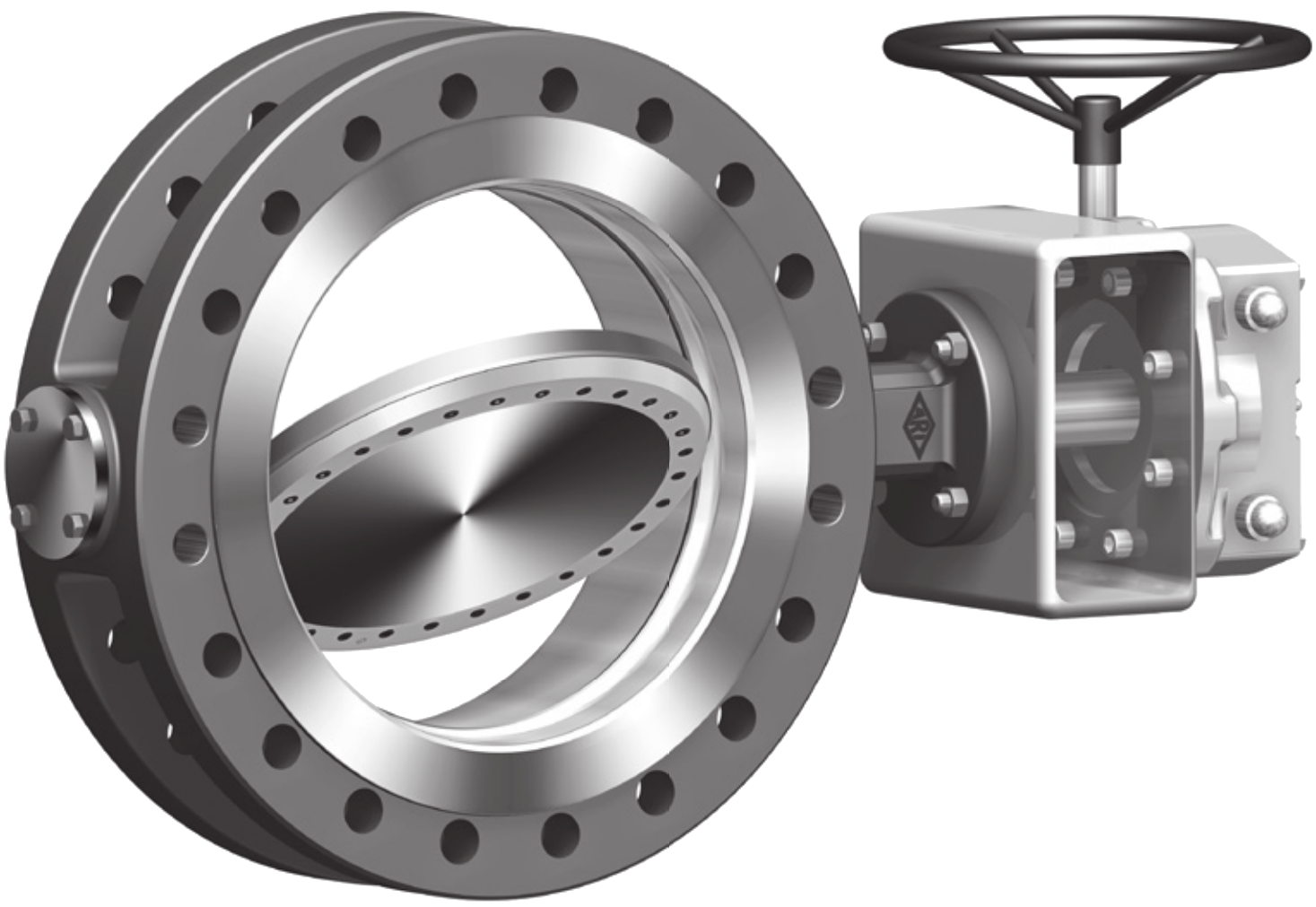

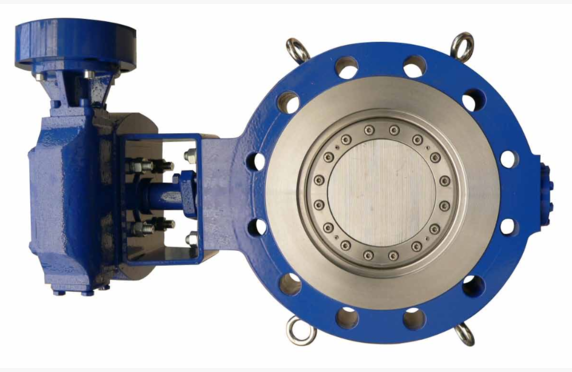

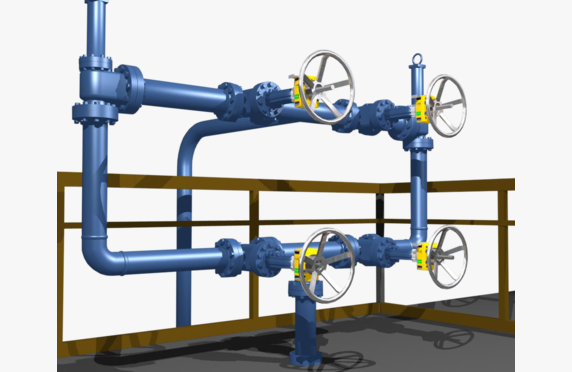

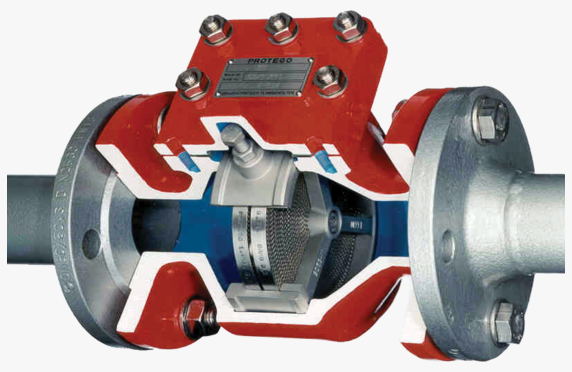

What is a teflon lined butterfly valve?

Teflon, or PTFE-lined butterfly valves, are designed for the reliable control of corrosive, toxic, abrasive, and explosive media.

Selection of a teflon lined butterfly valve

We assist in selecting and sizing a butterfly valve that meets the requirements of your application.

Garlock valves are known, among others, in the chemical, petrochemical, process, food industries and many other industrial sectors for their quality, performance, and reliable operation even in challenging conditions. Garlock butterfly valves are manufactured to meet the requirements of TA-Luft and the FDA, and they are SIL 2 certified according to the EN 61508 standard.

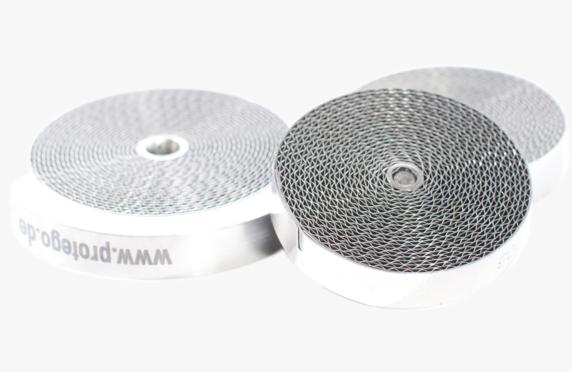

Garlock butterfly valves use PTFE (Polytetrafluoroethylene) lining due to its excellent chemical resistance. In Garlock’s manufacturing facility in Neuss, Germany, an isostatic casting process is used for the valve lining (the granules are compressed uniformly from all sides) to ensure product quality and durability.

Garlock GmbH Neuss – Germany is certified to EN ISO 9001:2008 and EN ISO 14001:2004.

Watch our YouTube overview of PTFE butterfly valves.

Garlock Butterfly Valve Product Lines

GAR-SEAL

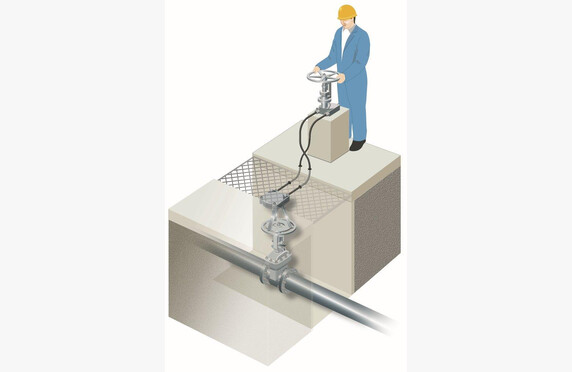

GAR-SEAL butterfly valves are widely used in various applications where corrosive, abrasive, or toxic media need to be controlled reliably. GAR-SEAL is used to throttle or shut off flow in facilities such as chemical, petrochemical, and paper manufacturing plants. The use of GAR-SEAL butterfly valves improves operational reliability and reduces maintenance costs.

MOBILE-SEAL

MOBILE-SEAL butterfly valves are used in tank vehicles, railcars, silos, and other transport and storage tanks where specialized safety requirements are needed. MOBILE-SEAL valves are EN 14432 approved.

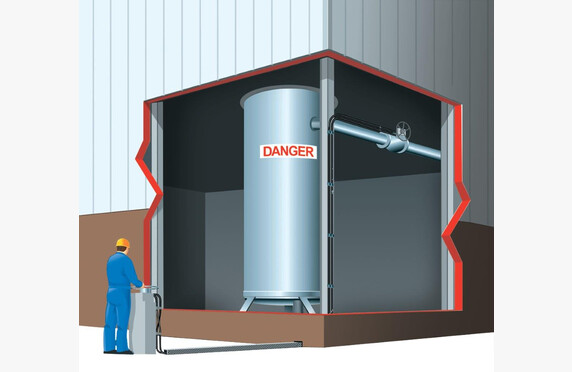

SAFETY-SEAL

SAFETY-SEAL butterfly valves are commonly used in applications where electrostatic charges must not be generated. This is achieved with conductive lining and grounding.

STERILE-SEAL

STERILE-SEAL butterfly valves are used in sterile processes, for example in the pharmaceutical and food industries. A special feature of this valve is its external sterilization readiness. Steam can be used to sterilize the “dead” zones of the valve without the steam coming into contact with the process medium.

TOXI-SEAL

TOXI-SEAL butterfly valves are used to control odor emissions in chemical, hazardous, or toxic applications where the release of a vaporizing medium into the environment must be prevented. The Garlock TOXI-SEAL butterfly valve is suitable for applications due to its leak-proof chamber and piston pressure seal.

VALVE ACCESSORIES

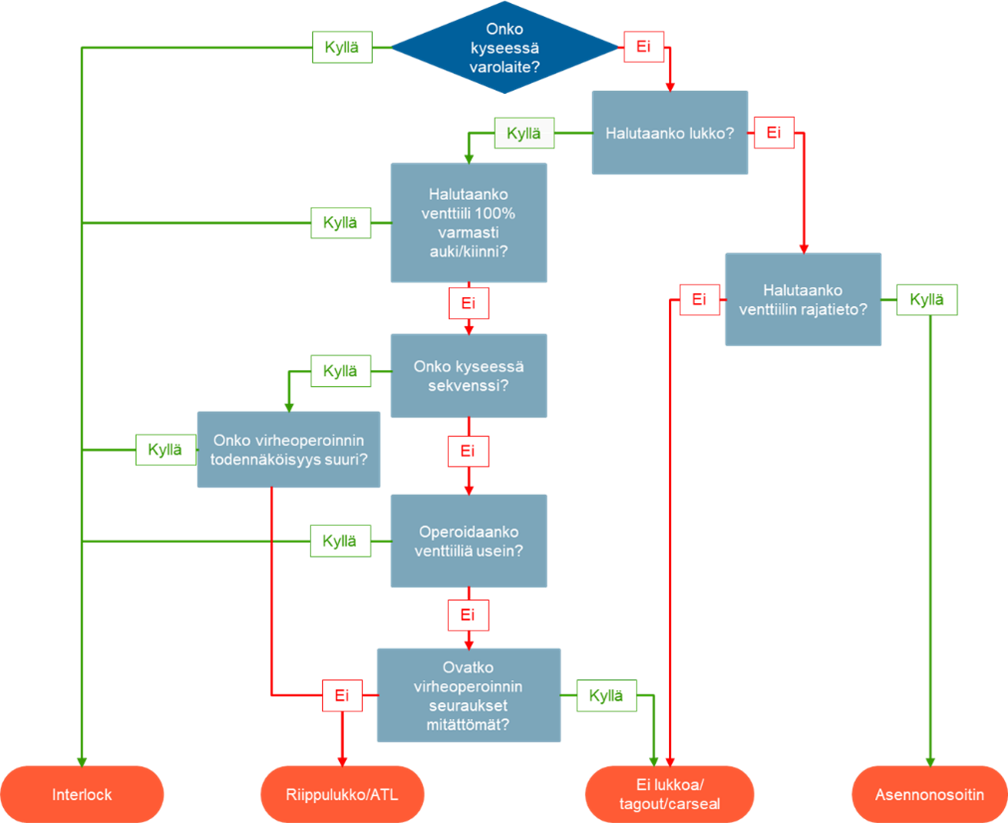

Garlock also offers a full range of valve accessories, such as special locking handles and gearboxes. The automation sector offering is comprehensive, including valve installation kits, actuators, limit switch devices, and valve positioners.

Download Brochures

Garlock Butterfly Valves

Lataa PDF